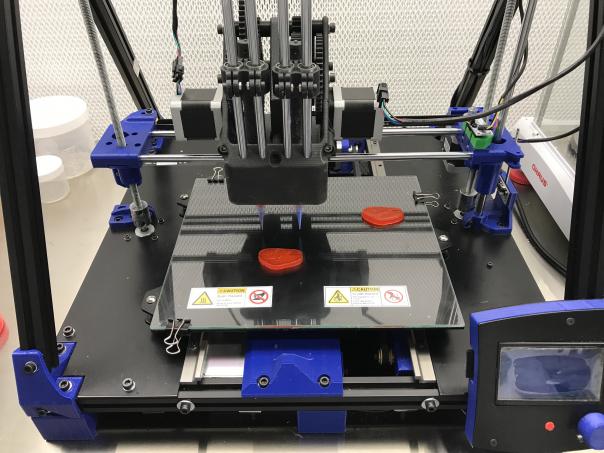

He says: "The idea of a 3D printed plant-based steak first came to me when I was working as a researcher and professor in Bioengineering at the UPC University in Barcelona last year. I was using a 3D bioprinter to create tissues which would serve as prototypes of artificial human organs, when I developed an ear-shaped structure that looked surprisingly realistic.

“I decided to show the ‘ear’ to some world-famous (and Michelin-star) Spanish restaurants and chefs who were very impressed, which prompted me to adapt the technology to create an edible plant-based meat, which I patented.

"As a flexitarian myself I think there’s an urgent need to revolutionise the food system and introduce more meat alternatives to help save our planet. In many ways I believe that our generation is lucky; we’re the first people in history with the technology and knowledge to be able to physically reverse climate change. If we can do it, we’ll be remembered for that.

"I decided to call the world’s first 3D printed plant-based steak Novameat. Nova means ‘new’ in Latin; I wanted to show that it’s a meat successor.

“There might be many plant-based burgers already on the market such as those found at Impossible Foods and Beyond Meat, and there are a plant-based meat substitutes which have the texture of meat and are soy or wheat gluten-based.

“The big difference with our technology, compared with these, is Novameat is a plant-based meat substitute which has the very same taste, texture, appearance and nutritional properties as real beef steak. We want to scale-up our technology as soon as possible to build bigger and more efficient machines that are more effective than 3D printers, which I believe will have a real impact the food system.

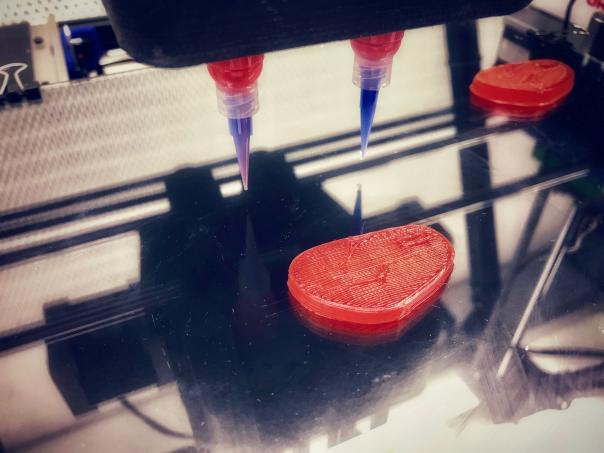

"At the moment, we have different versions of the first ‘meat’ prototype, most of them made of organic rice and pea proteins, and fibres from algae. However, the final set of ingredients will change in the next few months as we’re working with chefs to focus more on the taste and nutritional properties.

“We will of course do our best to select ingredients and suppliers that support organic farming and biodiversity.

"So far, we have developed the first prototype of the product, which only exhibits the texture of a steak. But I hope that we will be able to generate a proper plant-based steak substitute (which I would like to call Novameat 1.0) by the end of 2020.

“I hope to see our technology being used by big food manufacturers to produce plant-based meat alternatives on a widespread basis to hit UK shelves before 2022. We'll also partner with innovative restaurants too, to bring plant-based fibrous meat to a widespread audience even faster.

"The current prototype only has the texture of steak - not the same nutritional properties. In the near future after working with chefs and food development labs, we will also be able to vary and customise the nutritional properties of the meat which will help solve hunger issues in the poorest areas of the planet.

“For example, for the poorest parts of Africa we could offer ‘meat’ with extra proteins and vitamins. We could also provide personalised food for astronauts for space travels very soon. I do think it’s a possibility that when this plant-based meat is more widely available UK supermarkets and restaurants it could make a significant number of people turn vegan - or at the very least flexitarian. This will go a long way to impacting climate change."

* You can view a video of the 3D printing process here: https://youtu.be/9ycYAHtceTU

Video credits:

- Production: EIT-Food (eitfood.eu <http://eitfood.eu> )

- Editing: Víctor Luengo (enerofilms.com <http://enerofilms.com> )